Heinz Isler Model

– John Chilton and Paul Shepherd

This text was written by Paul Shepherd. The interjections, in italic, are additions by his friend and Heinz Isler expert John Chilton.

If you go down to the woods today…

Since our son was away on Scout camp all weekend, my plans for Sunday involved a much-needed lie-in and an episode, or three, of Columbo. But my other half had her own ideas. ‘We are going with E to see an art exhibition’ she said. It was not something I’d considered as an alternative, but E does get invited to some crazy things, so I negotiated an 11am departure and off we set.

When we pulled into an inconspicuous farm in the middle of nowhere, I assumed it was to ask for directions. But no, according to our GPS we had arrived at our destination, Shatwell Farm. We were greeted by Niall Hobhouse, who urged us to take a good look around the architectural delights of the farm and offered to show us the drawing collection once we had seen the art exhibition.

We walked around the site from building to building and experienced a range of different artworks from six artists selected for this year’s ‘Expositions’ exhibition, curated by Kendra Matchett. I use the word ‘experienced’ advisedly since one piece by Nicola Turner was located within an old grain silo. I entered the dark space to see the sculpture when, out of the corner of my eye, some of it began to move towards me. My exit was so swift I had to be told later that it was a dynamic piece, and that there were a couple of performance artists inside dressed in black to blend in as part of the sculpture.

I managed to lower my heart rate by viewing the rest of the exhibition and the various architectural gems dotted around the farm. I can’t think of anywhere else you can park next to columns by Álvaro Siza and then stroll past a cowshed by Stephen Taylor Architects before gazing at an obelisk by Alison & Peter Smithson. My personal favourite was Cedric Price’s library inside a pair of shipping containers. Not only was the selection of thousands of books inside inspiring (it was nice to see Derek Walker’s Great Engineers in amongst the architectural tomes, even if I don’t [yet] feature), but the clever positioning of the mirrors inside the space made it seem much bigger and less regularly set out than it really is. I later found this created significant challenges for the team from University College London who laser scanned it. As if that wasn’t enough, the Royal College of Art had installed a wonderfully contextualised outdoor shower and toilet from locally scavenged materials in the space between the containers, answering the age-old conundrum ‘does a bear shit in the woods?’ with a resounding yes.

After more than an hour of sensory overload, I was beginning to wonder if we might get back in time for the second episode of Columbo as we headed back to the car, with only the archive left to see. Niall was there, talking to other visitors, so we stepped across the threshold to take in the sheer number and quality of the drawings on display. I soon found my eyes were drawn, not to a drawing, but to a small model perched on the edge of one of the drawing cabinets in the centre of the room. And it was then that I got my nursery rhyme-inspired ‘big surprise’.

Now, a small fibreglass model of a concrete shell building might not seem much to the casual visitor. But, could it really be, hidden away in the woods among the cow sheds, that there was a real Heinz Isler shell in plain sight?

I’ve long been a fan of Isler. I was first introduced to his work through the International Association of Shell and Spatial Structures (IASS), of which I am a long-standing member and Isler was a founding and honorary member. Since then, I have developed ever-increasing respect for his work. This is perhaps slightly influenced by the possibilities reincarnation suggests, for Isler passed away on the same day my son was born and my son attended his first IASS International Symposium aged three months. But my admiration for Isler has less to do with the unique playfulness of his architectural style, and more with his pioneering use of scale physical models to determine efficient shapes for his buildings – a process known as (physical) form-finding.

Isler worked with a very simple yet powerful principle. He used flexible textiles (fabrics, mesh and nets) and let them hang downwards under gravity. The shape they fell into was naturally efficient as a hanging structure because the material was in pure tension under gravity and doesn’t resist any bending. If bending moments were present, they would cause the fabric to rotate and move to relax the bending, which means the shape that it eventually settles into is efficient for a tension structure since it can be built with a minimum of material required to take the load to its supports. Isler would literally freeze these hanging forms, stringing up his wife’s best towels between the branches of the trees in his office garden during the winter. After successive cycles of spraying and freezing, he would remove them from the trees and turn them upside down to use as scale models for future shell buildings.

John: In fact, Isler’s inverted hanging membrane form-finding technique was only applied for a relatively small number of his shells. For accurate modelling, he actually used a latex rubber sheet, which stretches equally in all directions, rather than woven textiles or nets. The latter materials were used for demonstration and exploration of form as in his experiments with ice shells. I don’t think he ever used towels but he certainly sprayed water onto large inflated balloons, draped garden netting and large sheets of fabric to create ice sculptures. The majority (literally hundreds…) of his shells were employed in industrial buildings. These were form-found with an inflated rubber membrane held in a rigid frame. A further technique exploited the form created by expansion of polyurethane foam within a fixed boundary, referred to as ‘flow-forms’. The pneumatic and flow-form techniques generate surfaces that are not purely in compression. Mostly, Isler captured the shape of his form-finding models with a layer of hardened gypsum plaster, although he has told of the problems he encountered when trying to measure the shape of an inflated membrane directly.

Concrete works efficiently in compression, and only needs reinforcement to deal with any tension. Therefore, using this technique to form-find a concrete dome leads to a logical shape that only needs nominal reinforcement to cope with the non-gravity loads that come from wind and uneven snow. Readers may be more familiar with the hanging-chain model now housed in the Sagrada Familia church in Barcelona, for which Antonio Gaudí used similar principles to determine the shape of stone blocks for the Church of Colònia Güell.

This principle is so powerful that it is still relevant to modern construction, and was the basis for a recent research project of mine to develop efficient concrete floors using computational design. By combining digital form-finding with robotic fabrication, my team and I managed to develop a thin-shell concrete floor system that uses only a quarter of the concrete of the equivalent flat-slab solution for the same loading conditions, simply by making sure the shell was in compression (which concrete likes) and not tension, meaning we could do away with traditional steel reinforcement bars completely.

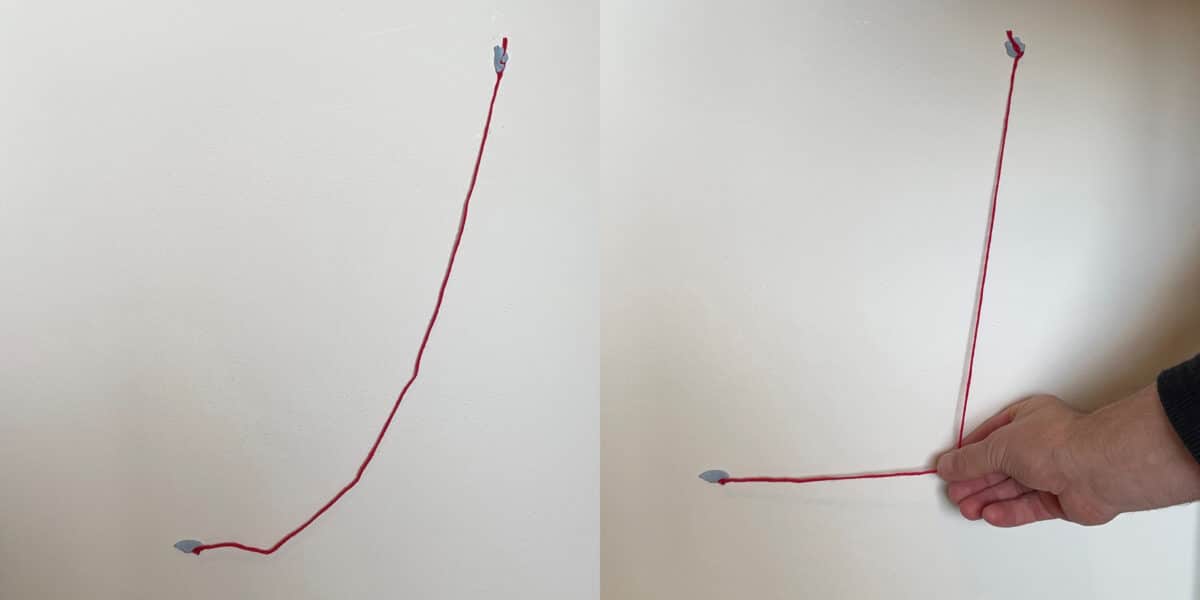

However, there was a problem down on the farm. The Isler shell on display did not look to me like it was based on a hanging form. The sides seemed to be very vertical where they touched the ground. This is uncharacteristic of a naturally formed hanging shape. In a hanging form, the sides tend to pull in, slowly turning the forces around the corner to relax the bending. In this model, the compression forces turn quickly and then straighten out, inducing bending. This is something perhaps better explained by blue-tacking some wool to the wall:

If this was an Isler model, and I had it on good authority that it was, which Isler shell was it? And why didn’t it conform to his modus operandi of form-found shapes? If you’ll forgive the spoonerism, this was not so much ShatWell Farm, but WhatShell Farm…

I was able to explain my confusion to Niall well enough for him to attempt to dig out the drawings that go with the model, but a combination of the slightly un-numerical filing system and the pressure of hosting others during the ‘Exposition’ weekend meant he was unable to easily find them. For now, the shell had to remain an unsolved mystery, but I set off home nevertheless intrigued and determined not to let it go unsolved for long. Whilst I had missed two episodes of Colombo, I did get back in time to see the third, where an architect murders his client and then buries him in a concrete pile. Colombo only works this out because the client had smashed up the architect’s scale site model, which seemed a perfectly fitting end to an interesting and completely unexpected day.

The very next day I turned to my friend and undisputed Isler expert, John Chilton. John wrote the book on Isler (quite literally), so if anyone would be able to help identify the shell, he would.

John: You would be very lucky to find a hard copy of my book, Heinz Isler: The Engineer’s Contribution to Architecture, which, sadly, has been out-of-print for many years. Used copies can sometimes be found but cost several times the original cover price: during a conference dinner a few years ago a colleague who had been trying to buy it showed me a copy offered online for €25,000! Luckily, a cheaper option is available through the Institution of Civil Engineers Virtual Library as an e-book.

I cut my long story short by editing out all the Columbo references, sent him a link to Drawing Matter Collections, and asked if he could do a bit of detective work to find out which shell it could be. I was not disappointed. As intrigued as I was, he replied:

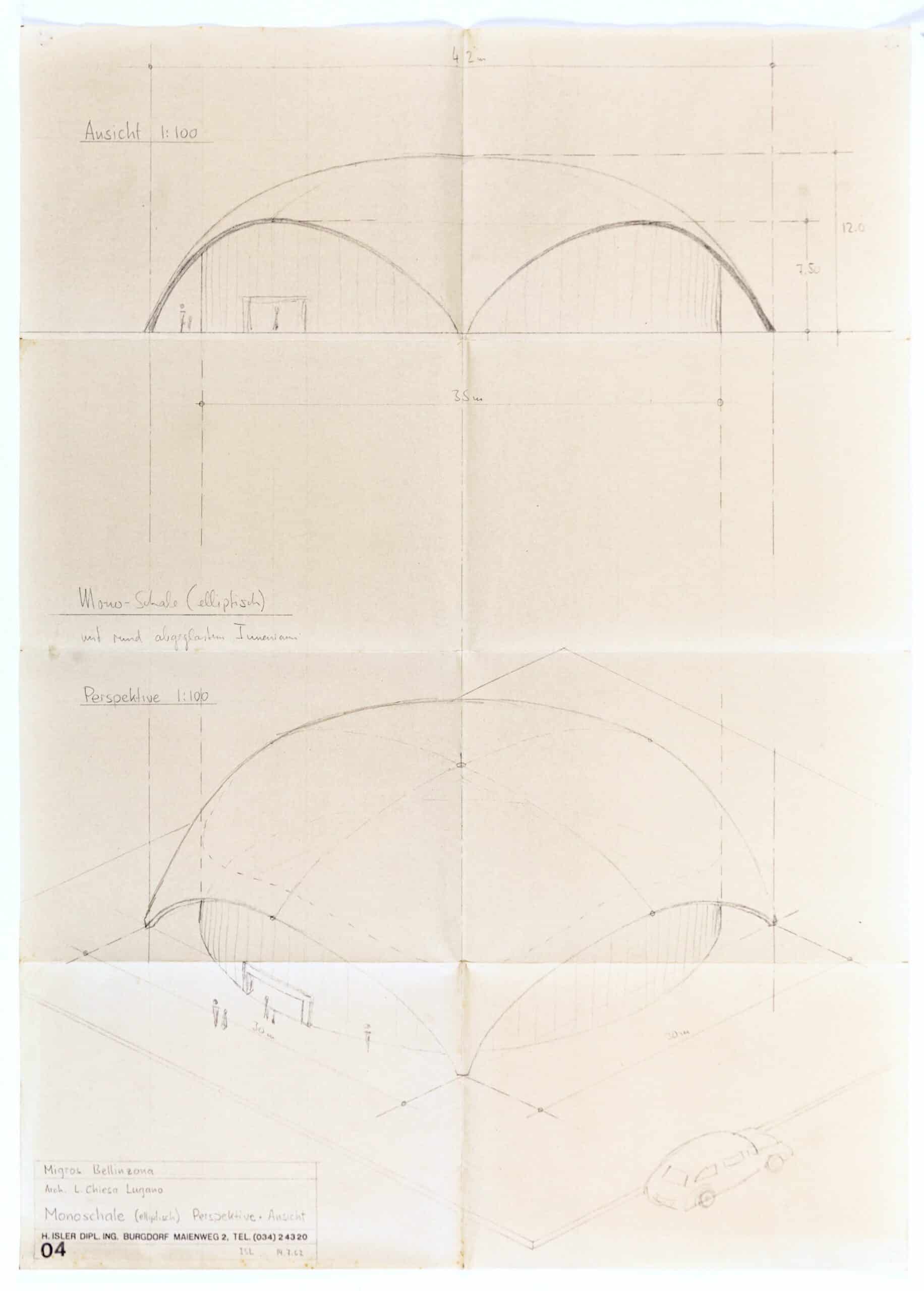

‘…the model looks like an early exploration for the Migros Supermarket, Bellinzona, completed in 1964. The associated drawing on the website suggests this and looks like an early sketch, as it’s dated 14 July 1962. Isler installed vertical prestress (hidden by glazing mullions) at the corners of this shell to reduce bending and avoid buckling. He also built a 1:10 model of it on the grounds of his office.’

John: This was my initial opinion, influenced by the model and drawing having been acquired by Drawing Matter at the same time. But I had my doubts; something did not feel right. As far as I was aware the Migros Supermarket, Bellinzona was the first Isler shell to be form-found with the ‘flow-form’ technique. The model looked more like an inflated form.

The drawing certainly matches the photograph of the finished building. And John’s revelation that there were prestressed tendons hidden inside glazing could well explain why the shape did not match my idea of what a naturally form-found shell should look like. Prestress can be used to pull a tension net into a different shape than that it would hang in naturally, and can change the flow of forces in a compression shell. This is similar to the effect of a flying buttress.

But to my mind, the drawing and building did not really seem to match the shape of the shell of the model, especially its long almost vertical ‘column’. This highlights the difficulties in ‘drawing’ a complex 3D form-found object for which there is no underlying constructional geometry.

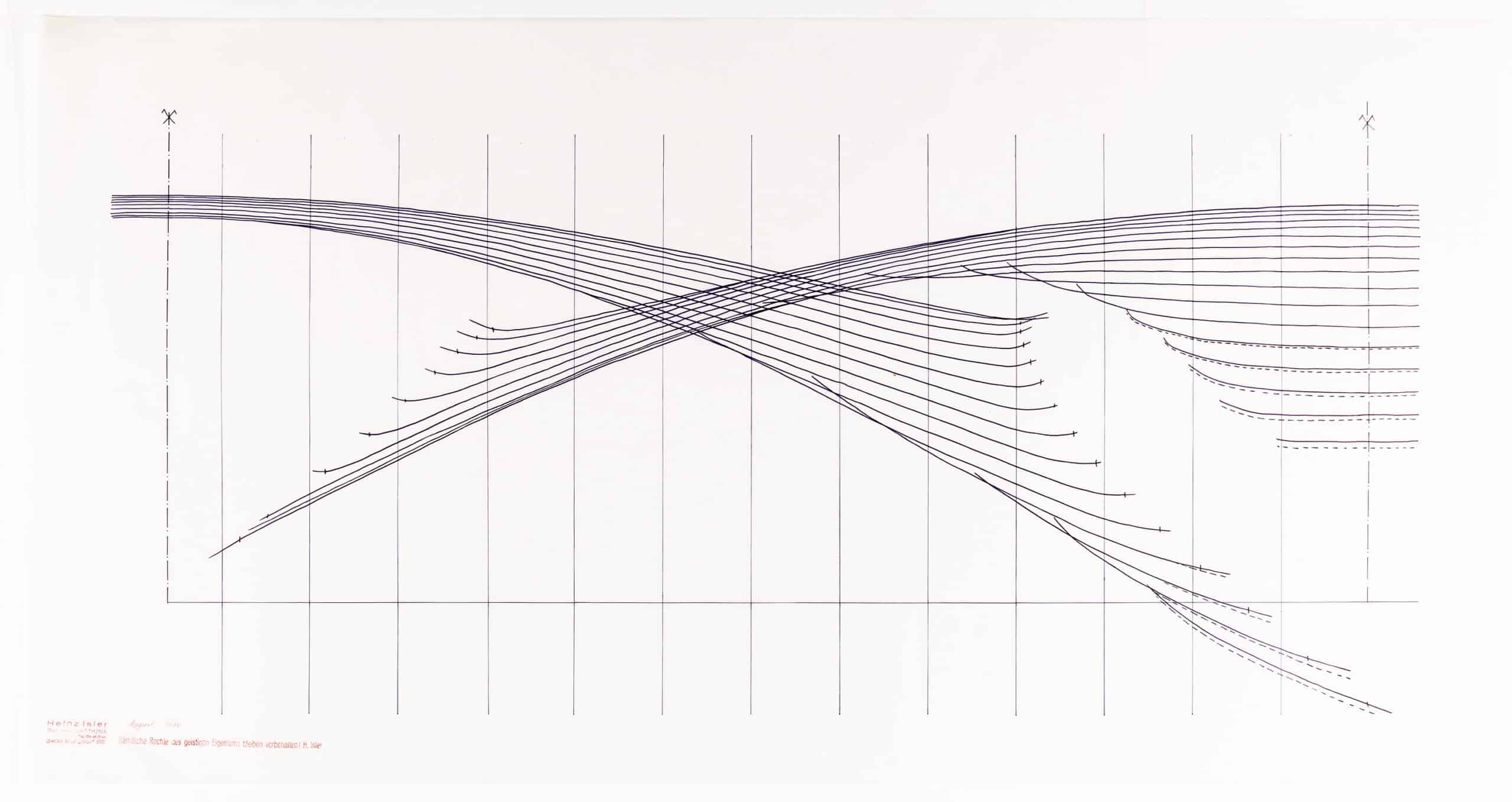

Isler was meticulous when measuring his physical models so as to be able to recreate their forms in 2D as construction drawings and for structural calculations. Inevitably this meant taking many sections throughout the building and representing the 3D form as a series of 2D curves.

John: As there are three different base heights, it seems that these plotted profiles are for the free-form shell on a sloping site, constructed for an outdoor theatre Naturtheater, Grötzingen, near Stuttgart, Germany, in 1977-78. In this case, the project architect and long-term Isler friend and collaborator, Michael Balz, carried out initial form-finding of the shell with a hanging model.

Frei Otto, an architect and contemporary of Isler, designed many fabric and shell structures using the same hanging-form principle. I worked on a project of his for the Stuttgart railway station concrete shell and was tasked with running computer analyses to calculate the compression forces in the shell at various points. Because the shape was so complex, I asked if they could email me their 3D model, to which I received the prompt reply, ‘There is no 3D CAD model. The 3D model is made from wire mesh and bolts and is currently taking up quite a lot of space in the centre of our office’. I ended up sending one of the luckiest work-experience students in history over to Otto’s studio in Stuttgart to digitise the 3D model using a metrology robot arm (the open mesh of the model made laser scanning difficult). My boss at the time wouldn’t let me go myself because my hourly charge-out rate was too high, and I still regret to this day not taking the time off as holiday and doing the scanning for free.

John: Isler was also involved with the Stuttgart 21 project as an advisor on the feasibility of the shell. He made a number of physical models to help him understand the flow of forces in the form. I understand that after initially supporting the design he concluded that it was not possible to construct the proposed form as a thin shell. As built, the ‘shells’ are relatively thick and heavily reinforced. Below is one of Isler’s exploratory models for Stuttgart 21, photographed in his office in 2011.

Niall was not idle either. Equally intrigued by the mystery, he commissioned some better photographs of the Isler shell and shared them with John, who revisited his earlier assumptions:

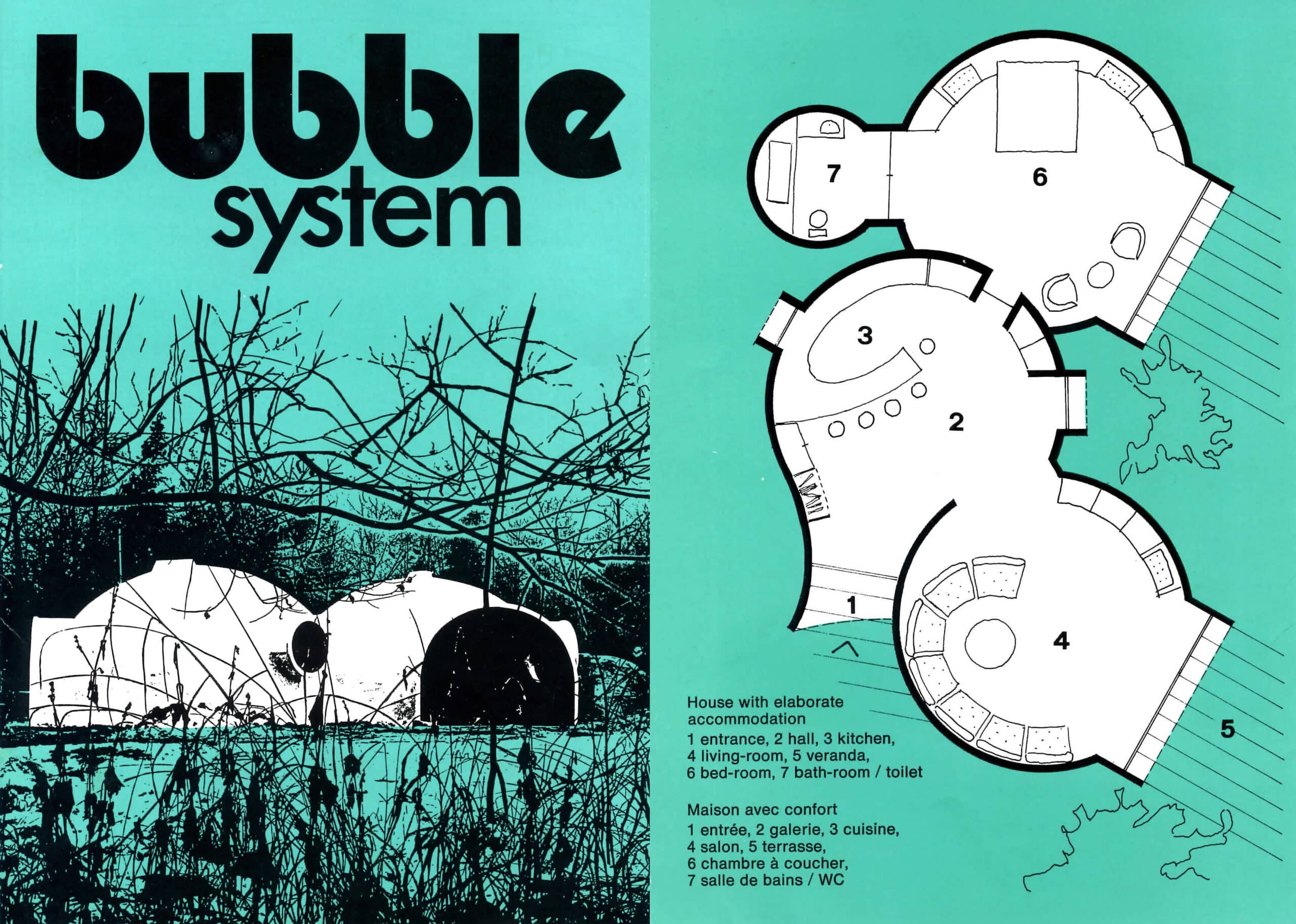

‘Now that I’ve seen the model from all angles, I think it is more likely to be related to the ‘Bubble System AG’ which was developed for shell housing (3000 units) proposed for a new city in Iran in the 1970s. Prototypes were built on the grounds of the Isler office. This is how they looked a few weeks ago…’

This does indeed look more like the model and features a similarly vertical wall. The difference here is that the shape has not been found from a pure hanging form with a focus on structural efficiency but has been designed around the fabrication process, spraying concrete onto a pneumatic formwork that can be reused many times to mass-produce a thin-shell structure.

John: My initial doubts were confirmed by the new photographs: it was a model of a pneumatic form and the vertical cuts represented the intersection of adjacent ‘bubble’ shells. The development of the ‘Bubble System AG’ is fully detailed in a conference paper by Matthias Beckh and Giulia Boller: Building with air: Heinz Isler’s bubble houses and the use of pneumatic construction techniques. Initially, in 1975, Isler was invited to develop the structural system for Swiss architect Justus Dahinden’s and Munich-based design firm Interplan’s proposal for pneumatic formed ‘bubble’ houses to be built in the new city of Moghan in northern Iran. These had a globular form, like a water droplet on a flat surface, and were composed of three layers – fast setting gypsum, reinforced insulating concrete and an acrylic rubber coating – on pneumatic formwork. Completed in a week, only one prototype shell was built in Iran before the project was cancelled due to the political and social unrest that led to the fall of the Shah in 1979. Isler told me this story, as we stood within the prototype bubble shells in his Lyssachschachen office grounds in August 1999.

With the cancellation of the Iranian project a more sophisticated version of the shell houses was developed, mainly for application in Europe, and the company Bubble System AG was founded by Isler with his contractor Bösiger AG, Frutiger Söhne AG, Hans Schmid AG, and François Prouvost. The refined system, which was composed of 60mm of reinforced gypsum, 40mm of insulation and 60mm of sprayed concrete painted for weather protection, had a vertical section of 1m at the base. This simplified construction and increased headroom within the shell. Few were built – namely, craft workshops at Ponthierry, near Paris and a motel at Al Baha, Saudi Arabia.

I think, like Colombo, we have probably solved this mystery. We have a good suspect in the mystery of the model, reasonably convincing evidence for a conviction, and a motive – to celebrate the work of a lesser-known pioneer of engineering.

– Mogens Prip-Buus